Maintenance Checklist How to Keep Your Pump System Running Efficiently Year-Round

Maintenance Checklist: How to Keep Your Pump System Running Efficiently Year-Round

Maintaining your pump system is crucial for ensuring reliable performance and preventing costly breakdowns. An effective maintenance checklist not only extends the lifespan of your equipment but also optimizes efficiency throughout the year. Whether you manage an industrial setup or a residential system, understanding the right practices for routine inspection and care can help minimize energy consumption and downtime. This guide provides a comprehensive checklist and expert tips to keep your pump system running smoothly in every season, supporting operational excellence and peace of mind for property owners and facility managers alike.

Key Highlights

- Proactive preventive maintenance is essential to maximize pump efficiency, reliability, and lifespan while reducing unexpected breakdowns and costly repairs.

- Routine inspections, thorough cleaning, and precise maintenance logs help quickly identify and address issues before they escalate.

- Regularly inspecting seals, bearings, filters, and alignment curbs wear, boosts performance, and reduces energy consumption.

- Early troubleshooting of abnormal noises, leaks, or energy spikes avoids downtime and supports continuous pump operation.

- A detailed, adaptable maintenance checklist and recordkeeping streamline maintenance, enhance compliance, and empower year-round pump system success.

Pump Maintenance Essentials for Year-Round Efficiency

Keeping your pump system running efficiently year-round hinges on diligent and proactive pump maintenance, which ensures your system stays reliable, energy-efficient, and cost-effective. Whether you’re looking to protect your well-maintained water system, maximize energy savings, or avoid unexpected repairs, establishing a strong preventive maintenance plan is the foundation. Regular maintenance and accurate maintenance logs offer peace of mind by reducing downtime and extending pump lifespan. Understanding why preventive maintenance matters and how it leverages both predictive maintenance and routine checks is essential for long-term system success. Explore what sets effective pump maintenance apart and learn strategies to keep your system consistently productive. Reliability and longevity become much easier to achieve when you integrate these essentials into your approach.

Understanding the Importance of Preventive Maintenance for Your Pump System

Embracing preventive maintenance is the smartest move for any pump system owner aiming to keep operations uninterrupted and costs low throughout the year. A well-designed maintenance plan addresses every component of your system, from installation to routine maintenance, ensuring that each pump, whether it’s serving industrial, commercial, or municipal needs, runs as intended. Having a solid pump maintenance strategy isn’t just about meeting manufacturer requirements; it’s about proactively avoiding issues that can lead to major repairs, wasted energy, or even total system failure. Regular monitoring through comprehensive maintenance logs allows you to catch early signs of trouble, like vibration anomalies, leaks, or overheating, before they escalate. This approach drives greater efficiency and extends the life of your pumps, translating into lower energy consumption, minimized operational costs, and increased uptime. Depicting the rationale behind pump preventive maintenance starts with acknowledging how neglect leads to avoidable pitfalls. Systems that skip scheduled checks often face hidden problems that go undetected until a critical breakdown interrupts production. Engaging in consistent inspections and predictive maintenance empowers teams to check pump parameters such as pressure, flow, and temperature, making it easier to spot wear patterns and potential system issues early. Leveraging this information, facility managers develop adaptable maintenance plans, taking into account seasonality, pump application, and installation environment. Whether the system handles water transfer, wastewater, or specialized fluids, maintenance logs fuel decisions that support both immediate remedial actions and long-term modifications for improved reliability. The benefits of prioritizing preventive maintenance include decreased frequency of emergency repairs, reduced stress on energy resources, and sustained compliance with industry safety standards. Regular maintenance tasks like lubrication, seal examination, and alignment checks reduce friction and wear, directly contributing to better efficiency and lower risk of breakdown. On top of that, adopting a culture of scheduled pump maintenance helps teams recognize patterns, anticipate future maintenance needs, and avoid costly downtime. By integrating this mindset into your daily operations, every aspect of pump maintenance, from repairs to predictive maintenance, functions as a cohesive unit. Partnering with pump maintenance professionals and using guidance from trusted resources like Pump Professionals ensures that your maintenance plan remains robust and adaptive in any setting. A well-maintained water system is more than just a series of machines; it’s the result of continuous, attentive care that balances energy usage and operational demands. With the right attitude towards preventive maintenance and detailed, up-to-date maintenance logs, every check pump routine serves as a safeguard against costly repairs and unexpected failures. Your pump system becomes a model of productivity and resilience when you make preventive maintenance a true priority, ensuring your investments are guarded and your operations can thrive all year. Let’s make efficiency the new normal with a comprehensive, detail-driven, and proactive approach to pump system care.Proper preventive maintenance can greatly extend pump system life and boost reliability. Key tasks every owner should prioritize include:

- Regularly inspect for leaks, unusual noises, and vibration to catch issues early.

- Check and maintain proper lubrication of bearings and moving parts as specified by the manufacturer.

- Monitor and clean filters, strainers, and suction lines to ensure unobstructed flow.

- Periodically align pump and motor shafts to prevent wear and energy loss.

- Examine seals and gaskets for signs of wear or deterioration; replace as necessary.

- Verify electrical connections and controls for corrosion, tightness, and proper function.

- Record performance data such as flow rates and pressures to detect trend changes. Consistently applying these simple tasks keeps your pump system operating smoothly and helps avoid costly downtime.

Routine Maintenance Tasks to Prolong Pump Lifespan

Adopting a routine maintenance schedule is key to keeping pumps operating at peak performance, minimizing the risk of sudden failures and costly repairs. Thoughtfully planned maintenance tasks not only support the core goals of system reliability and efficiency but also create a proactive culture that prevents issues before they begin. Committing to routine inspections, meticulous cleaning, and keen attention to every pump component means smoother operations all year. Structured approaches to maintenance logs, component maintenance, and timely repairs safeguard your investment and minimize downtime, making your pump maintenance plan as effective as possible. Understanding key inspection points and implementing thorough cleaning strengthens your preventive maintenance efforts.

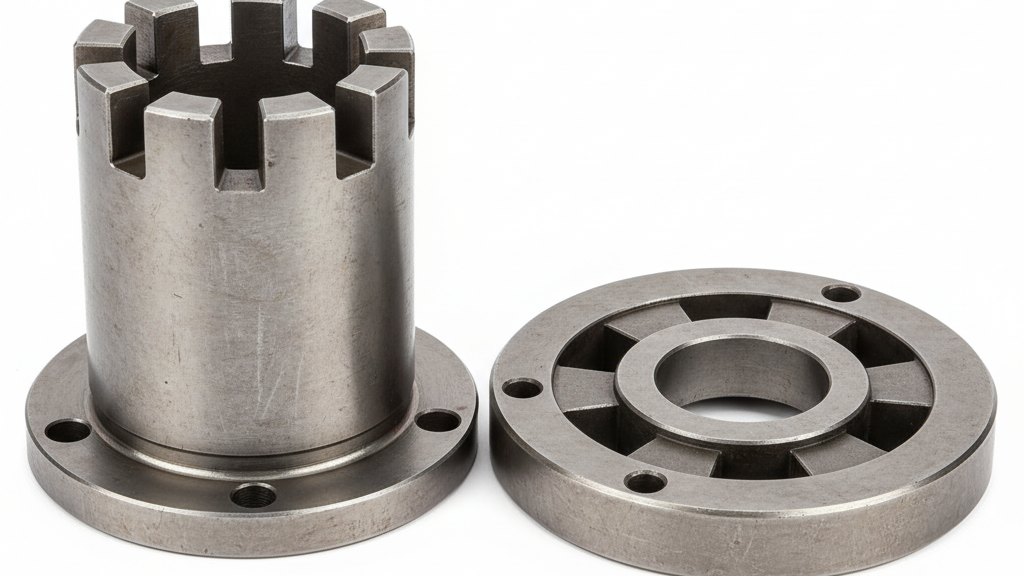

Key Inspection Points and Cleaning Steps for Pump Components

A well-executed routine maintenance schedule forms the backbone of reliable pump performance, extending the lifespan of pumps and optimizing system energy consumption. Consistently following maintenance checklists, including specific key inspection points for each pump component, helps you identify wear or potential breakdowns long before they escalate into expensive repair or replacement situations. The process begins with comprehensive inspections. Take the time to check pump housings for corrosion, leaks, or physical damage, making sure any abnormal noises or vibrations are logged for further analysis. Examine seals at every maintenance interval; any sign of leakage may indicate the need for prompt seal replacement to avoid additional pump maintenance issues down the line. Inspecting for proper alignment between pump and motor primed, and ensuring coupling guards are secure, should be part of your routine maintenance plan. An inspection of internal pump components is equally important, focusing on impeller wear, shaft integrity, and bearing condition. Noticing irregularities at these key inspection points makes it much easier to anticipate future maintenance or required repair. To further optimize preventive maintenance, carefully observe all mounting bolts and supports to confirm that vibration hasn’t loosened them over time. Cleaning plays a pivotal role in maintenance, especially for pumps that process fluids prone to leaving deposits or buildup. Scheduling regular cleaning sessions helps to keep internals free from debris, scaling, or other contaminants, which, if left unchecked, can severely disrupt flow rates and energy efficiency. Use approved cleaning solutions and techniques, never abrasive substances, for internal surfaces, and always closely follow manufacturer recommendations. Don’t forget filters and strainers: their presence is crucial in shielding internal pump components from particulates that could otherwise damage seals or clog passages. For optimal preventive maintenance, clean or replace these filters routinely, and note each action in your maintenance logs. Checking thermostat settings during your maintenance schedule supports energy efficiency and can lessen the load on your pumps during high-demand periods. Overheated systems solicit more frequent pump repair, while a stable operating temperature, monitored via inspection and routine maintenance, keeps the entire system running smoothly. Another essential element is maintaining clear and up-to-date maintenance logs. Detailed records document which inspection points have been covered, when components were last cleaned or replaced, and what repairs have been performed. This documentation provides both historical insight and guidance for future preventive maintenance strategies. Establishing a component maintenance approach not only enhances reliability but also supports compliance with warranty or manufacturer policies. Whether a system needs minor adjustments or a complete replacement, an ongoing maintenance schedule helps you act before problems escalate. By routinely inspecting, cleaning, and tracking every aspect of the pump system, including all seals, filters, and housings, you align the maintenance plan to the real-world requirements of your unique installation environment. Sometimes, staying on top of routine maintenance means leveraging outside expertise. Resources such as trusted pump manufacturers and maintenance partners provide valuable insights into best practices, troubleshooting, and component replacement. Tapping into their knowledge supports effective pump maintenance while reinforcing your own team’s ability to address system needs confidently. Ultimately, embedding these inspection and cleaning steps into your maintenance schedule transforms the reliability and longevity of every pump in your facility. Thorough preventive maintenance creates the foundation for continuous uptime, fewer unplanned repairs, and optimal flow throughout your system, making sure your operations are dependable, efficient, and prepared for the demands of every season.

How to Identify and Troubleshoot Common Pump Issues

Recognizing and addressing pump issues promptly is a crucial part of maintaining your system’s performance and longevity. Building on solid preventive and routine maintenance practices, quickly identifying the signs of wear or malfunction can prevent costly repairs or replacements. Proper troubleshooting, paired with accurate maintenance logs, helps reduce downtime and boosts overall efficiency. Experienced teams rely on structured approaches to detect early indicators like abnormal pump noises, reduced flow, or unexpected energy spikes. By understanding these warning signs and knowing the right solutions, you can enhance your maintenance strategy, streamline repairs, and ensure your pumps keep water and other fluids flowing smoothly year-round.

Signs of Wear and Solutions to Maintain Pump Performance

Consistent pump maintenance helps you spot the early signs of wear that threaten both system reliability and pump performance. High-performing pumps generate specific noise profiles and flow rates; sudden changes signal issues demanding prompt attention. For instance, excessive vibration or rattling often suggests makeshift repairs or a deviation in routine maintenance, possibly stemming from loosened mounting bolts, misalignment, or internal component degradation. Rely on maintenance logs to track and trend these events, enabling more accurate troubleshooting when issues arise and improving your preventive maintenance and repair outcomes. Another undeniable sign of wear is diminished flow or a drop in water pressure, especially if system demands haven’t changed. A build-up of debris or scaling within pump components, worn impellers, or partially blocked seals are typical culprits. Frequent inspections and scheduled cleaning, guided by historical maintenance logs, prevent such issues from escalating. When cleaning doesn’t resolve reduced flow, investigate for potential seal failure, a leading cause of water leaks and system inefficiency. If you notice persistent leaks, replacement of those seals should be prioritized to avoid further pump damage and possible repair or replacement of larger components. Log each seal inspection or replacement in your maintenance logs to assist predictive maintenance strategies and future troubleshooting. Energy consumption spikes are another red flag for underlying pump maintenance problems. If your pump’s energy usage increases without a clear system reason, worn bearings, inefficient seals, or buildup reducing internal clearance may be to blame. Detailed comparative analysis of maintenance records and energy data gives valuable insights for pinpointing the trouble spots. This can guide targeted repairs rather than costly trial-and-error approaches. For persistent electrical or performance fluctuations, conduct predictive maintenance using sensor data for a more precise view of pump health, an approach proven to extend system lifespan and minimize total repair events. Unusual smells or heat generation around the pump or its motor can reveal urgent pump issues, ranging from inadequate lubrication to failing bearings or electrical faults. Be sure to incorporate these elements into your maintenance checklist, as running a pump under such conditions significantly accelerates wear and increases operating costs. Immediate pump shut-down and a thorough troubleshooting protocol, documented in your maintenance logs, should follow any identification of these critical issues. Proper documentation not only streamlines pump repair but also supports ongoing system optimization and reliability. Seals are often the first components to show visible signs of wear, and damage to seals directly correlates to water leaks, reduced pump efficiency, and corrosion of critical internals. Consistent attention to seal condition during inspections, combined with swift replacement as part of your maintenance routine, preserves optimal pump performance. All such findings and actions should be detailed in your maintenance logs, which form the backbone of your ongoing preventive maintenance and repair history. Establishing a culture of routine and predictive maintenance, driven by clearly defined troubleshooting processes, ensures your pumps reach their maximum potential lifespan while minimizing the frequency and severity of repairs. Using maintenance logs not only helps track issues and solutions but also enables continuous process improvement and compliance with industry standards. By prioritizing regular inspections, energy monitoring, and diligent repair or replacement of worn components, your system remains reliable, cost-effective, and capable of delivering the water flow and pump performance your operations demand season after season.

Downloadable Pump Maintenance Checklist for Ongoing Success

A robust maintenance checklist is the cornerstone for achieving ongoing success with your pump system. This checklist acts as a practical, day-to-day guide to keep your maintenance routine on track, ensuring nothing gets missed that could compromise system reliability or efficiency. When developing a maintenance checklist, integrating elements like a flexible maintenance schedule, detailed maintenance logs, and plans for both preventive maintenance and prompt repairs will maximize your system’s performance throughout the year. It empowers operators to perform routine inspections, document critical observations, and consistently evaluate each pump component to quickly address issues before they require expensive repair or full replacement.

Downloading a comprehensive pump maintenance checklist eliminates the guesswork from pump care by establishing a consistent framework for your maintenance team. When you’re managing multiple pumps or systems within your facility, having a defined schedule ensures all essential checks and servicing are performed on time, from routine lubrication and seal inspection to monitoring system operating parameters and initiating timely component replacement. The checklist serves as both a reminder and a record, supporting systematic completion of every maintenance item, which is especially important when tracking compliance or warranty requirements. Log every completed task, whether it’s a minor installation check or a more involved repair, to bolster predictive maintenance strategies and continually refine your maintenance plan.

Preventive maintenance is at the heart of any effective maintenance checklist. Integrated cleaning routines, regular visual inspections, and precise calibration of system components are all included to minimize the risk of emergency repairs or premature pump replacement. The checklist makes it simple to check pump housings for leaks, vibration, and unusual noises that may signal underlying wear. It also helps teams identify when filters, seals, or bearings require cleaning or replacement, and prompts regular examination of mounting bolts and alignment. By using a checklist, you bring greater structure to maintenance, ensuring nothing is overlooked during day-to-day operations or during larger-scale system reviews or installation of new pumps.

Proper documentation is also a critical part of ongoing pump maintenance. The maintenance checklist should be accompanied by up-to-date maintenance logs, which capture observations, maintenance actions, and details about repairs or replacement activities. Over time, these logs reveal trends that can inform more effective maintenance schedules and help justify decisions around repair or future installation of new equipment. When you combine a detailed checklist with disciplined recordkeeping, preventive maintenance becomes a proactive process, minimizing unplanned downtime, supporting both immediate repair and long-term replacement strategies, and driving the ongoing success of your pumps and overall system.

This downloadable maintenance checklist isn’t just a document; it’s a living plan developed to adapt to any facility’s unique needs. Update it regularly as you adjust your maintenance priorities, address failures, or bring new pumps and system components online. With your checklist and logs guiding every inspection, cleaning routine, repair, or replacement, your pump maintenance program remains dynamic and reliable. Harness the power of structured pump maintenance. Download your checklist today and build your maintenance schedule for year-round success.

Sticking to a thorough maintenance checklist is the foundation for ensuring your pump system operates at peak efficiency all year long. Regular inspections, proactive servicing, and prompt repairs extend equipment life, prevent unexpected breakdowns, and save energy costs. By implementing these best practices, you safeguard your investment and ensure optimal performance no matter the season. For expert advice or tailored maintenance schedules, consult with a professional to keep your pump system running smoothly. A little attention today can prevent costly issues tomorrow, helping you achieve reliable, worry-free operation throughout the year.

FAQs

Why is preventive maintenance important for pump systems?

Preventive maintenance maximizes pump efficiency, reliability, and lifespan while reducing unexpected breakdowns and costly repairs. Regular maintenance, including inspections and cleaning, helps catch issues before they escalate, saves energy, and ensures your system operates efficiently year-round.

What should be included in a pump maintenance checklist?

A comprehensive checklist should cover:

– Visual inspection for leaks, corrosion, and damage

– Check of seals, bearings, alignment, and filters

– Inspection of mounting bolts and supports

– Cleaning internal components, strainers, and filters

– Monitoring vibration, noise, and energy use

– Maintenance log updates for all tasks and observations

How can I identify early signs of pump issues?

Look for abnormal noises, increased vibration, reduced flow or water pressure, persistent leaks, energy consumption spikes, and unusual heat or smells near the pump. Accurate maintenance logs help track these warning signs and guide targeted troubleshooting steps.

How often should pump maintenance be performed?

Pump systems should receive inspections and maintenance according to manufacturer recommendations and operating conditions, but generally:

– Monthly: Visual checks, cleaning, and log updates

– Quarterly: More thorough inspections and lubrication

– Annually: Complete system review and deep cleaning

Adjust frequency based on usage intensity or environment.

What role do maintenance logs play in pump system care?

Maintenance logs track all inspection findings, maintenance actions, repairs, and component replacements. They provide a historical record for trend analysis, support warranty and compliance requirements, and improve future preventive and predictive maintenance planning.