Pump Maintenance Schedule: A Q1 Checklist for Sump and Effluent Systems

As the first quarter of the year begins, it’s the ideal time to ensure your sump and effluent pump systems are operating efficiently. Preventative maintenance during Q1 helps avoid costly repairs, unexpected downtime, and potential system failure during peak usage months. Whether you’re managing residential, commercial, or municipal pumping systems, implementing a reliable Q1 maintenance checklist ensures long-term performance and compliance.

At Pump Professionals, we understand the critical role that sump and effluent pumps play in waste and stormwater management. A consistent maintenance routine safeguards your system’s reliability and helps identify minor issues before they become major problems. Below is a comprehensive Q1 checklist tailored to sump and effluent pump systems that you can use to guide your service and inspection schedule.

Why Q1 Maintenance Is Crucial for Pump Systems

The first quarter of the year presents unique challenges for pump systems. In many regions, increased groundwater from snowmelt and early rains can strain sump pumps. Additionally, cooler temperatures can cause equipment to contract, increasing the risk of seals or fittings loosening or failing.

Effluent systems, responsible for pumping gray water or treated wastewater, can also experience blockages or wear due to heavier use during the holiday season. Conducting inspections and servicing early in the year allows property managers, facility operators, and homeowners to proactively manage their systems before spring storms and higher flow demands arrive.

Q1 Maintenance Checklist for Sump and Effluent Pump Systems

1. Inspect Pump Operation

- Test the pump’s automatic float switch to ensure it activates and deactivates correctly.

- Listen for unusual noises during operation, such as grinding, rattling, or humming.

- Verify that the pump starts and stops at the correct water levels and cycles efficiently.

2. Clean and Remove Debris

- Clear the sump pit or basin of silt, gravel, and other accumulated debris that may clog the intake.

- Ensure discharge lines are free of obstructions, ice, or buildup.

- Check inlet screens and filters for clogs or buildup and clean them thoroughly.

3. Inspect Electrical Components

- Check power cords for wear or damage and ensure they are securely plugged into a GFCI outlet.

- Test backup power sources, including battery backups and alarms.

- Inspect control panels and alarm systems for signs of moisture intrusion, corrosion, or malfunction.

4. Examine Pump Seals and Fittings

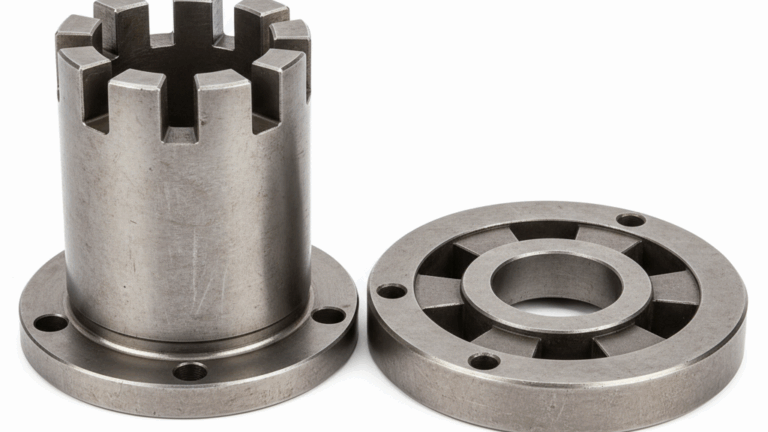

- Inspect mechanical seals for leaks or cracks.

- Tighten all fittings and check for signs of wear or corrosion.

- Ensure discharge pipes are firmly connected and not vibrating or leaking under pressure.

5. Assess Pump Performance Metrics

- Measure flow rate and compare to baseline performance data.

- Check for short cycling or inconsistent pressure levels, which can indicate pump wear or obstruction.

- Document any signs of decreased efficiency for future reference and planning.

6. Flush the System (If Applicable)

- Flush effluent systems to remove residue or solids that may affect performance.

- Use manufacturer-approved cleaning solutions if necessary to maintain system integrity.

7. Review Maintenance Logs and System History

- Update maintenance records with current observations and service actions taken.

- Identify recurring issues that may signal the need for repair or component replacement.

- Schedule professional inspections or service as needed based on usage and condition.

When to Call the Pump Professionals

While basic pump maintenance can be handled in-house, certain conditions require the expertise of trained professionals. If your system shows signs of reduced efficiency, persistent noise, electrical issues, or water leaks, it’s time to schedule a detailed inspection.

The team at Pump Professionals offers specialized maintenance and service programs for sump and effluent systems across a wide range of industries. With decades of experience in pump system troubleshooting, repair, and replacement, our technicians can help you extend the lifespan of your equipment and prevent costly failures.

Benefits of Professional Q1 Pump Maintenance

- Early Detection of Issues: Identify minor concerns before they become major failures.

- Improved Efficiency: Ensure pumps are operating at peak performance and within design parameters.

- Regulatory Compliance: Meet environmental and municipal codes with professionally maintained systems.

- Extended Equipment Lifespan: Reduce wear and tear with regular service and preventative care.

- Customized Service Plans: Receive tailored maintenance plans that match your pump’s unique operational demands.

Industries That Benefit from Regular Pump Maintenance

Pump systems are critical in a wide range of environments, and maintenance should be customized based on industry-specific conditions. Some of the sectors that benefit most from routine Q1 maintenance include:

- Residential and multifamily properties

- Commercial buildings and retail facilities

- Municipal wastewater and stormwater systems

- Industrial and manufacturing facilities

- Food processing and hospitality services

Each of these settings has distinct flow rates, contaminants, and wear patterns, making professional maintenance and inspection crucial for dependable operation year-round.

Schedule Your Q1 Pump Maintenance Today

Don’t wait for flooding, backups, or pump failure to disrupt your operations. Use Q1 as a proactive window to review your sump and effluent systems and get ahead of potential problems. Regular pump maintenance not only protects your investment but also ensures your systems perform reliably when it matters most.

Contact us today to schedule a comprehensive inspection and customized maintenance plan for your sump and effluent pump systems. Our team is ready to keep your systems running smoothly into Q2 and beyond.