Pump Maintenance Made Simple: Your Q1 Checklist for Sump & Effluent Systems

As we transition from winter to spring, the first quarter presents an ideal opportunity to conduct thorough drainage pump maintenance on your sump pump and effluent pump systems. After months of handling groundwater and wastewater through harsh winter conditions, these critical components require systematic inspection and preventive care to ensure operational readiness for the challenging months ahead.

Implementing a comprehensive first quarter maintenance protocol not only extends equipment longevity but also prevents costly pump failure during peak demand periods. This quarterly inspection guide outlines essential maintenance best practices that every property manager and facilities professional should incorporate into their maintenance calendar to maximize pump reliability and system performance.

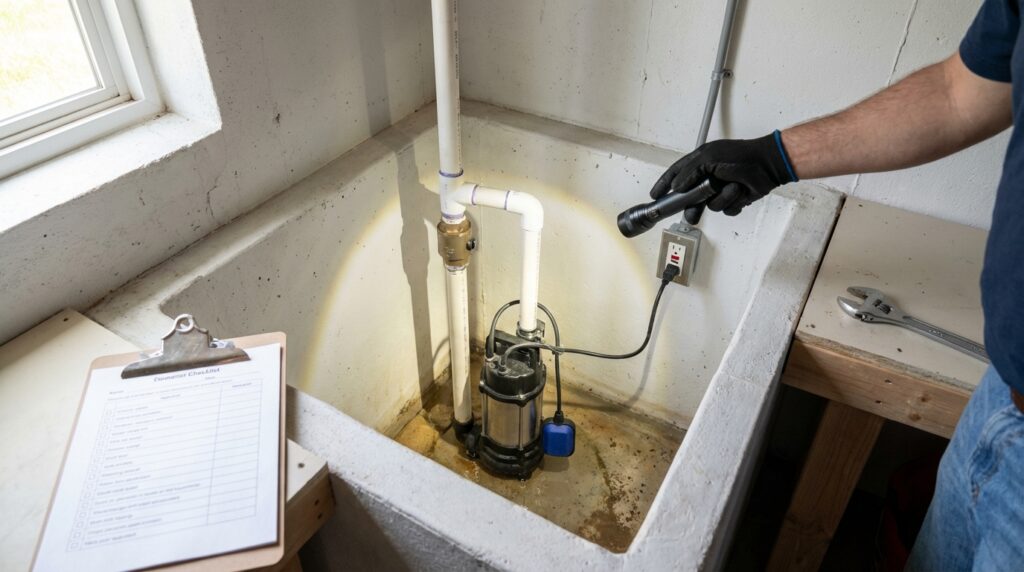

Critical Sump Pump Inspection Points and Component Assessment

Begin your quarterly sump pump inspection checklist by examining the pump housing, basin, and intake screen for accumulated debris or sediment buildup. These areas frequently collect materials that compromise pump efficiency and can lead to premature wear. Clear the weep hole, inspect the check valve for proper seating, and verify that the discharge pipe remains unobstructed and securely fastened.

The float switch requires particular attention during Q1 pump maintenance tasks, as mechanical components often experience wear from continuous pump cycle operations. Test the level sensor functionality by manually lifting the float mechanism, observing smooth movement without binding. Additionally, examine the motor housing for unusual heat signatures or moisture infiltration that could indicate developing mechanical seal compromise or bearing assembly deterioration.

Motor Inspection and Electrical Testing Procedures

Conduct a comprehensive voltage test and amp draw measurement to establish baseline electrical performance metrics. Compare these readings against the pump manufacturer specifications to identify any deviations that might signal electrical components degradation. Verify that the GFCI outlet functions correctly and that the circuit breaker maintains appropriate amperage ratings for your specific pump capacity and horsepower requirements.

Inspect all wiring connections within the control panel for corrosion, loose terminals, or damaged insulation. The pump controller should display normal operational parameters, and any alarm system indicators must be tested to confirm they activate under simulated failure conditions. This electrical maintenance component proves essential for both submersible pump and pedestal pump configurations.

Effluent Pump Service Requirements and Performance Monitoring

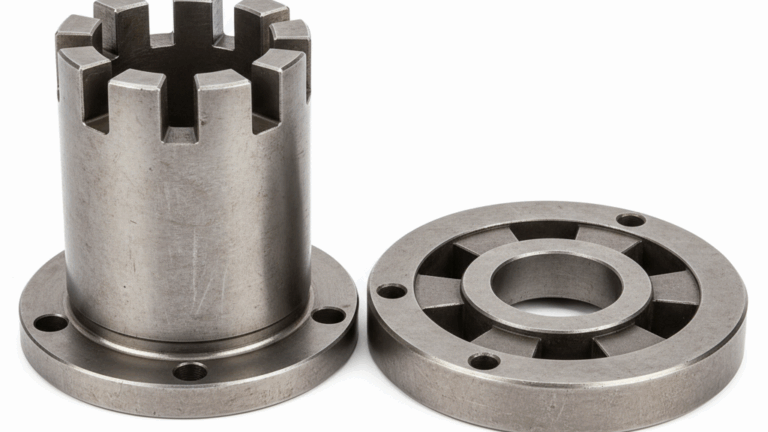

Effluent pump quarterly service requirements differ slightly from sump pump protocols due to their interaction with septic system wastewater. Examine the pump impeller for material accumulation or damage, as fibrous materials frequently impact flow rate and head pressure capabilities. The volute housing should be inspected for wear patterns, and the shaft examined for alignment issues that affect bearing performance.

Runtime monitoring establishes crucial baseline data for pump troubleshooting and condition assessment throughout the operational lifecycle. Document current pump cycle frequency, noting any changes from previous quarterly pump inspection procedures. Unusual runtime patterns often indicate developing problems with the pressure switch, mechanical seal, or changes in system demand that require immediate attention.

Backup Pump Testing and Reliability Verification

Your backup pump represents the final defense against system failure, making quarterly maintenance frequency absolutely critical. Test the battery backup system under load conditions, verifying adequate voltage and capacity to operate the pump through extended outage scenarios. Inspect all O-ring and gasket seals on backup equipment, as dormant systems often develop leaks that only manifest during emergency activation.

Simulate primary pump failure to confirm automatic backup pump engagement occurs seamlessly. This reliability testing validates that your grease fitting, bearing assembly, and all mechanical maintenance requirements have been properly addressed, ensuring true redundancy when circumstances demand it.

Maintenance Documentation and Service Schedule Optimization

| Maintenance Task | Service Interval | Critical Components |

|---|---|---|

| Visual Inspection | Monthly | Basin, Float Switch, Discharge Pipe |

| Electrical Testing | Quarterly | Motor, Control Panel, GFCI Outlet |

| Component Replacement | Annual or As Needed | Check Valve, Mechanical Seal, Bearings |

Establishing comprehensive Q1 pump maintenance documentation creates invaluable historical records for pump health checks and facilitates strategic maintenance planning. Record all inspection findings, amp draw measurements, runtime data, and component replacement activities to identify trends that inform preventive maintenance program optimization and equipment lifecycle management decisions.

Consider engaging a qualified plumbing contractor for specialized system diagnostics that exceed routine servicing capabilities. Professional pump preservation services provide advanced performance evaluation tools and expertise that complement your internal routine maintenance protocols, ensuring comprehensive system upkeep and maximum drainage system reliability throughout the operational year.

Frequently Asked Questions

How often should I perform preventive maintenance on my sump pump during Q1?

Comprehensive quarterly inspections should occur once during the January through March period, with monthly visual checks of the float switch, basin cleanliness, and discharge pipe integrity. Additionally, conduct weekly monitoring of pump cycle frequency and runtime patterns to detect emerging issues early, particularly following heavy precipitation or snowmelt events common during the winter to spring transition.

What are the most common causes of effluent pump failure in the first quarter?

The primary failure modes include mechanical seal degradation from continuous wastewater exposure, pump impeller damage from fibrous materials in septic system effluent, and electrical components corrosion from moisture infiltration during winter months. Float switch malfunction and check valve failure also rank among frequent Q1 issues, particularly in systems that experienced increased cycling during winter groundwater fluctuations.

Should I replace my sump pump battery backup system annually?

Battery backup system replacement typically follows a three to five-year service interval, depending on usage frequency and environmental conditions. However, quarterly testing during Q1 maintenance reveals actual capacity degradation, allowing data-driven replacement decisions. If voltage testing shows capacity below seventy percent of rated specifications or runtime monitoring indicates significant performance decline, immediate replacement ensures continued reliability regardless of installation age.

What documentation should I maintain for my pump maintenance schedule?

Comprehensive maintenance documentation should include inspection dates, visual condition assessments, electrical test results including amp draw and voltage measurements, runtime data with pump cycle frequency, component replacement records with part specifications, and any anomalies observed during routine servicing. This maintenance calendar information proves invaluable for warranty claims, regulatory compliance in commercial applications, and optimizing preventive care strategies based on actual equipment performance trends.