Grinder Pumps for Wastewater Management: Comprehensive Guide to Pressure Sewer Systems and Sewage Grinding Technology

# Grinder Pumps for Wastewater Management: Essential Solutions for Modern Sewage Systems

As professionals in the wastewater infrastructure industry, we understand that effective sewage conveyance remains one of the most critical challenges facing residential and commercial property owners today. When traditional gravity sewer systems prove impractical or impossible to implement, grinder pumps emerge as the definitive solution for reliable wastewater management. These sophisticated devices have revolutionized how we approach decentralized wastewater treatment and sewage system retrofit projects across diverse property types.

Throughout my years working with municipal sewer authorities and private wastewater collection systems, I have witnessed firsthand how properly selected and maintained grinder pump systems transform properties that would otherwise remain undevelopable. The technology behind waste grinding and pressurized collection has evolved significantly, offering property owners dependable alternatives to conventional gravity-fed infrastructure.

TL;DR Summary

Grinder pumps are specialized submersible pumps that macerate solid waste into fine slurry before pumping it through small-diameter pipes to municipal sewer systems or treatment facilities. They provide essential solutions for low-lying property drainage, uphill sewage pumping, and remote property sewer connections where gravity systems cannot function. Understanding pump sizing calculation, maintenance protocols, and proper installation requirements ensures reliable wastewater management with minimal operational disruption.

Understanding Grinder Pump Technology and Cutting Mechanisms in Wastewater Systems

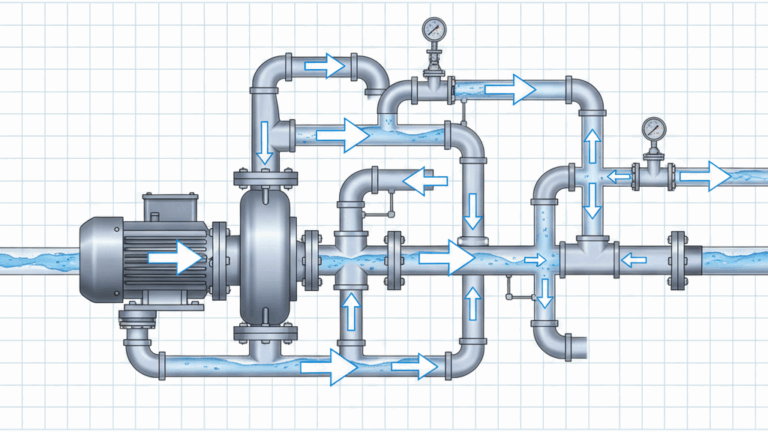

A grinder pump represents a specialized category of submersible sewage pump designed specifically for solids handling through advanced maceration technology. Unlike standard effluent pumps that handle only pre-settled liquids, grinder pumps incorporate precision-engineered cutting mechanisms that reduce solid waste materials into a homogeneous waste slurry suitable for transport through pressure sewer systems.

The fundamental architecture consists of a sealed electrical motor connected to a rotating impeller equipped with hardened steel blades or cutting teeth. As wastewater enters the pump chamber from residential wastewater or commercial wastewater sources, the cutting mechanism systematically shreds toilet paper, organic matter, and other flushable materials into particles typically measuring three-eighths of an inch or smaller. This solids reduction process enables the resulting slurry to flow smoothly through small diameter sewer lines without obstruction or blockage.

Grinder Pump Components and Operational Architecture

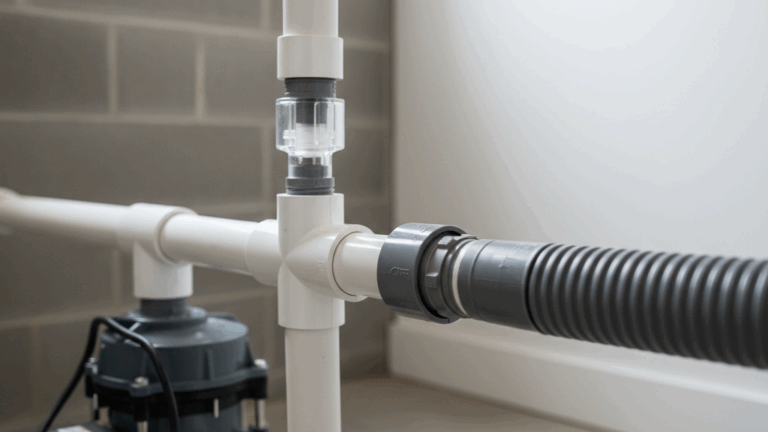

The comprehensive system includes several critical elements working in concert to ensure reliable pump-assisted drainage. The holding tank or basin serves as the collection point, typically ranging from 30 to 300 gallons depending on property requirements and pump cycling frequency considerations. Within this pump chamber installation, the submersible pump remains submerged, protected by thermal overload protection to prevent motor damage during extended operations.

A sophisticated control panel manages pump activation through float switch technology that monitors wastewater levels. When influent reaches predetermined thresholds, the electrical system energizes the motor, initiating the grinding and pumping sequence. The discharge pipe, equipped with essential check valve and shut-off valve components, directs the pressurized waste slurry into the forced sewer main connecting to municipal infrastructure or on-site treatment facilities.

Grinder Pump Versus Effluent Pump and Sewage Ejector Pump Distinctions

Professionals frequently encounter confusion regarding the functional differences between various sewage pump technologies. Understanding these distinctions proves essential for proper system specification and wastewater infrastructure planning. Each pump category addresses specific application requirements and wastewater characteristics.

| Pump Type | Solids Handling Capability | Typical Application | Discharge Head Pressure | Primary Function |

|---|---|---|---|---|

| Grinder Pump | Macerates all solids into fine slurry | Direct connection to pressure sewer system | High (typically 50-150 PSI) | Complete wastewater grinding and conveyance |

| Effluent Pump | Handles only pre-settled liquids | Septic system effluent disposal | Moderate (20-50 PSI) | Clear liquid transfer from septic tanks |

| Sewage Ejector Pump | Passes solids up to 2 inches | Basement sewage removal to gravity line | Low to moderate (15-40 PSI) | Below-grade wastewater elevation to gravity system |

Grinder pumps distinguish themselves through their ability to process raw sewage containing solid waste materials. The sewage maceration capability enables connection to low-pressure sewer networks utilizing significantly smaller pipe diameters than conventional gravity systems require. This fundamental advantage makes grinder pump systems ideal for alternative sewer system applications where traditional infrastructure proves economically prohibitive or physically impossible.

Pressure Sewer System Implementation and STEP System Design

Low-pressure sewer technology, often implemented as Septic Tank Effluent Pump (STEP) systems or grinder pump-based pressure sewerage, represents a paradigm shift in wastewater collection methodology. These pumped sewer systems eliminate the need for deep excavation, extensive trenching, and large-diameter piping associated with gravity sewer alternatives.

In pressure sewer configurations, individual grinder pump stations at each property generate sufficient discharge head pressure to convey wastewater through small diameter sewer mains ranging from 1.25 to 4 inches. This pressurized collection approach accommodates challenging topography, high water tables, and remote property sewer connections that would otherwise require cost-prohibitive infrastructure investments.

Residential and Commercial Grinder Pump Sizing and Hydraulic Capacity

Proper pump sizing calculation represents perhaps the most critical factor determining long-term system reliability and operating cost analysis. Undersized equipment results in excessive pump cycling frequency, premature component failure, and inadequate hydraulic capacity during peak demand periods. Conversely, oversized systems incur unnecessary capital expenditure and reduced pump energy efficiency.

The pump performance curve, provided by manufacturers such as Zoeller Company, Liberty Pumps, Grundfos, Environment One Corporation (E/One), and Myers Pumps, graphically illustrates the relationship between flow rate measured in gallons per minute (GPM) and total dynamic head measured in feet of elevation. Professional specification requires analyzing both parameters relative to site-specific conditions.

Critical Factors in Grinder Pump Selection

Several variables influence appropriate equipment selection for wastewater pumping station applications:

- Daily wastewater generation volume: Residential properties typically produce 50-75 gallons per person per day, while commercial wastewater varies substantially based on facility type and occupancy patterns

- Vertical elevation requirements: The distance wastewater must be lifted from the pump chamber installation to the connection point with municipal sewer or treatment facilities

- Horizontal distance specifications: The linear footage of discharge pipe between the grinder pump basin and destination, including friction losses through fittings and valves

- Horsepower rating requirements: Typically ranging from 1 to 2 horsepower for residential applications, with commercial installations requiring higher ratings based on demand

- Voltage specifications and amperage draw: Electrical infrastructure must accommodate pump requirements, typically 230V single-phase for residential or 460V three-phase for commercial systems

Environmental Protection Agency (EPA) guidelines and local code authorities often mandate specific performance criteria that equipment must satisfy. Working with qualified grinder pump contractors ensures compliance with applicable regulations while optimizing system performance.

Installation Requirements and Pump Pit Design Considerations

Proper grinder pump installation establishes the foundation for reliable long-term operation. The wet well configuration must accommodate adequate storage volume to minimize pump cycling while preventing extended retention periods that encourage septic conditions. Professional pump chamber installation typically involves several critical steps that directly impact system functionality.

Essential Components of Professional Grinder Pump Tank Installation

The basin or sump structure requires careful sizing based on anticipated wastewater volumes and desired pump cycling patterns. Industry best practices generally recommend minimum pump run times of one minute to prevent motor overheating while limiting cycles to approximately 15-20 per day under normal operating conditions. This balance protects equipment longevity while ensuring adequate hydraulic capacity during peak usage periods.

- Excavation and foundation preparation: The pump vault must rest on stable, compacted substrate or engineered concrete pad preventing settlement or structural compromise

- Basin installation and backfill procedures: Proper grading and drainage around the holding tank prevents groundwater infiltration and maintains structural integrity

- Discharge pipe routing and support: The force main requires proper bedding, adequate slope for drainage during maintenance, and protection from freezing in cold climates

- Electrical connection and control panel mounting: All wiring must comply with National Electrical Code requirements, with appropriate overcurrent protection and disconnection means

- Safety device installation: Check valve, gate valve, vacuum breaker, and backflow preventer components ensure proper system operation and prevent sewage backup

- Alarm system configuration: High-water alarm notification systems provide early warning of pump failure or excessive inflow conditions

Electrical Requirements and Safety Protection Systems

The control panel serves as the command center for grinder pump operations, housing circuit protection, pump controls, and alarm circuitry. Modern installations incorporate sophisticated monitoring capabilities including remote alarm notification system connectivity enabling property owners and service providers to receive immediate alerts regarding operational anomalies.

Thermal overload protection embedded within the electrical motor prevents catastrophic failure during abnormal operating conditions. This safety feature automatically disconnects power when internal temperatures exceed safe thresholds, protecting the substantial capital investment these systems represent.

Maintenance Schedule and Pump Maintenance Protocol for Longevity

Even the most robust waste grinding technology requires systematic maintenance to ensure optimal performance throughout its anticipated lifespan. Manufacturers typically project equipment longevity of 10-15 years for residential grinder pump applications when properly maintained, with commercial installations potentially requiring more frequent attention due to elevated duty cycles.

Establishing a comprehensive pump maintenance protocol minimizes unexpected failures while controlling long-term operating costs. Property owners and facility managers should understand both routine maintenance tasks and indicators requiring professional intervention from qualified grinder pump service companies.

Routine Maintenance Tasks for Grinder Pump Systems

- Monthly alarm system testing: Verify proper float switch operation and audible alarm function to ensure early warning capabilities remain operational

- Quarterly visual inspection: Examine control panel indicators, check for unusual sounds during pump operation, and verify proper cycling behavior

- Annual professional servicing: Qualified technicians should inspect internal components, test check valve operation, verify discharge head pressure, and assess cutting mechanism condition

- Three to five-year comprehensive evaluation: Detailed pump performance curve analysis, motor insulation testing, and basin condition assessment identify developing issues before failure occurs

Common Grinder Pump Problems and Troubleshooting Procedures

Understanding typical failure modes enables faster diagnosis and resolution when issues arise. The most frequent complications in wastewater grinder pump systems include:

| Symptom | Probable Cause | Recommended Action | Prevention Strategy |

|---|---|---|---|

| Alarm activation without pumping | Float switch malfunction or pump motor failure | Cease water usage; contact service provider immediately | Annual float switch replacement; regular testing |

| Frequent cycling with low water usage | Check valve failure allowing backflow | Professional check valve maintenance or replacement | Valve inspection during annual service |

| Reduced flow or weak discharge | Cutting mechanism wear or discharge pipe obstruction | Professional inspection of impeller and discharge line | Avoid flushing inappropriate materials; regular servicing |

| Unusual noise during operation | Damaged impeller, worn bearings, or debris interference | Immediate professional evaluation to prevent complete failure | Proper waste disposal practices; routine maintenance |

Preventive maintenance consistently proves more economical than reactive repairs. The grinder pump repair cost for emergency service calls and expedited component replacement typically exceeds the investment in systematic maintenance schedules by substantial margins.

Cost Analysis and Operating Cost Considerations

Financial planning for grinder pump systems encompasses both initial capital investment and ongoing operational expenses. Understanding the complete lifecycle maintenance cost structure enables informed decision-making regarding equipment selection and alternative sewer system implementation.

Installation Cost Factors and Budget Planning

The cost of installing a grinder pump for wastewater varies significantly based on site conditions, equipment specifications, and regional labor rates. Typical residential grinder pump installation costs range from $4,000 to $12,000, encompassing equipment, basin, electrical work, and professional installation services. Commercial grinder pump wastewater applications generally require larger capital investments reflecting increased capacity requirements and more robust equipment specifications.

Factors influencing installation expenditure include:

- Equipment quality and manufacturer selection (premium brands like Environment One grinder pump systems command higher prices but offer superior reliability)

- Basin size and structural requirements for the grinder pump tank

- Electrical infrastructure modifications to accommodate voltage specifications and amperage draw

- Discharge pipe length and complexity of routing to connection points

- Site preparation requirements, particularly challenging soil conditions or high water tables

Operational Expenses and Energy Consumption Analysis

Beyond capital costs, property owners should evaluate ongoing grinder pump energy consumption and routine maintenance expenses. Pump energy efficiency directly impacts operating costs, with modern variable frequency drive technology offering substantial savings compared to traditional constant-speed motors.

Typical residential grinder pump systems consume between 0.5 and 1.5 kilowatt-hours per day under normal operating conditions, translating to monthly electrical costs of $5-15 depending on local utility rates. Annual maintenance expenses, including professional servicing and routine component replacement such as float switch and check valve refresh, generally range from $150-400 for residential applications.

Leading Manufacturers and Equipment Selection Guidance

The grinder pump market features several established manufacturers recognized for engineering excellence and product reliability. Selecting equipment from reputable sources ensures access to replacement components, technical support, and warranty coverage protecting your wastewater infrastructure investment.

Top Grinder Pump Brands for Wastewater Management Applications

Environment One Corporation (E/One) pioneered low-pressure sewer technology and remains the industry leader in grinder pump innovation. Their sealed bearing design and proprietary cutting technology deliver exceptional reliability for both residential and commercial applications.

Liberty Pumps offers comprehensive product lines addressing diverse wastewater pumping requirements. Their residential grinder pump systems feature simplified maintenance access and robust construction suitable for demanding service conditions.

Zoeller Company combines over 80 years of pump manufacturing expertise with modern engineering. Zoeller grinder pump systems emphasize serviceability and component longevity, with many installations exceeding 20-year operational lifespans.

Grundfos brings European engineering precision to the wastewater market. Grundfos grinder pump technology incorporates advanced monitoring capabilities and exceptional pump energy efficiency for reduced operating costs.

Myers Pumps, a subsidiary of Pentair, delivers value-oriented solutions without compromising performance. Myers grinder pump offerings serve cost-conscious projects while maintaining reliability standards.

Regulatory Compliance and EPA Guidelines for Wastewater Infrastructure

Professional wastewater management requires thorough understanding of applicable regulations governing system design, installation, and operation. The Environmental Protection Agency (EPA) establishes federal standards complemented by state and local requirements that vary by jurisdiction.

Grinder pump installations must typically satisfy specifications addressing minimum basin capacity, alarm system requirements, electrical safety standards, and discharge criteria. Many municipalities mandate specific equipment certifications or pre-approved manufacturer lists for pressure sewer system connections. Engaging qualified grinder pump contractors familiar with local code requirements prevents costly compliance issues and ensures permit approval.

Recent regulatory trends emphasize decentralized wastewater management as communities seek alternatives to expensive centralized treatment plant expansions. This regulatory environment increasingly favors grinder pump technology as municipalities implement alternative sewer system programs addressing previously unserved areas.

Future Innovations in Waste Transfer Pump Technology

The wastewater management industry continues evolving, with manufacturers investing substantially in technological advancement. Emerging innovations promise enhanced reliability, reduced energy consumption, and improved monitoring capabilities that will further strengthen the value proposition of grinder pump systems.

Smart pump technology incorporating Internet-of-Things connectivity enables predictive maintenance protocols that identify developing issues before failure occurs. These systems provide real-time performance data, usage analytics, and remote diagnostics that reduce service costs while maximizing uptime. Cloud-based alarm notification systems deliver instant alerts to property owners and service providers through smartphone applications, ensuring rapid response to operational anomalies.

Advanced materials science continues improving cutting mechanism durability and corrosion resistance. Ceramic-enhanced cutting surfaces and specialized alloy compositions extend maintenance intervals while maintaining grinding effectiveness across diverse waste stream compositions.

Conclusion: Strategic Value of Grinder Pumps in Modern Wastewater Infrastructure

Grinder pump technology represents an indispensable component of contemporary wastewater management infrastructure. These sophisticated systems enable development and sewer service in locations where traditional gravity systems prove impractical or prohibitively expensive. From remote property sewer connections to basement sewage removal and uphill sewage pumping applications, grinder pumps deliver reliable performance that property owners and municipalities depend upon daily.

Success with grinder pump systems requires informed equipment selection based on rigorous pump sizing calculation, professional installation adhering to best practices, and systematic maintenance schedules protecting long-term investment value. Partnering with experienced grinder pump service companies and selecting quality equipment from established manufacturers like E/One, Liberty Pumps, Zoeller, Grundfos, or Myers ensures optimal performance throughout the system lifecycle.

As wastewater infrastructure professionals, we recognize that properly implemented grinder pump installations deliver decades of trouble-free service while providing flexibility that gravity systems cannot match. The technology continues advancing, offering enhanced capabilities that will further expand application possibilities and improve operational efficiency.

Whether addressing residential wastewater management challenges or designing comprehensive commercial wastewater collection systems, grinder pump technology deserves serious consideration as part of your wastewater infrastructure planning process. The combination of technical capability, economic efficiency, and installation flexibility positions these systems as optimal solutions for countless applications.

Frequently Asked Questions

What is the difference between a grinder pump and a sewage ejector pump for wastewater management?

A grinder pump features precision cutting mechanisms that macerate all solid waste into fine slurry, enabling conveyance through small-diameter pressure sewer systems under high pressure (50-150 PSI). Sewage ejector pumps simply transfer wastewater with solids up to 2 inches to nearby gravity sewer lines at lower pressures (15-40 PSI) without grinding. Grinder pumps are designed for direct connection to low-pressure sewer networks, while ejector pumps handle basement sewage removal to conventional gravity systems.

How much does grinder pump installation cost for residential wastewater systems?

Residential grinder pump installation costs typically range from $4,000 to $12,000, depending on equipment selection, basin size, electrical requirements, discharge pipe length, and site conditions. Premium manufacturers like Environment One Corporation may cost more initially but offer superior reliability and warranty coverage. Additional factors affecting cost include excavation complexity, distance to municipal sewer connection, and local labor rates. Professional installation by qualified grinder pump contractors ensures code compliance and optimal system performance.

What maintenance schedule should I follow for my grinder pump system?

Grinder pump maintenance protocols should include monthly alarm system testing, quarterly visual inspections of control panel indicators and operational sounds, annual professional servicing by qualified technicians including check valve inspection and cutting mechanism evaluation, and comprehensive three to five-year assessments with pump performance curve analysis. Regular float switch testing and proper waste disposal practices (avoiding flushing inappropriate materials) significantly extend equipment lifespan. Following manufacturer-recommended maintenance schedules prevents costly emergency repairs and maximizes system reliability.

Can grinder pumps handle all types of waste in wastewater systems?

Grinder pumps effectively macerate human waste, toilet paper, and typical organic bathroom materials into fine slurry suitable for pressure sewer conveyance. However, certain items should never enter grinder pump systems: feminine hygiene products, dental floss, cloth materials, plastic items, grease, chemicals, and non-biodegradable materials can damage cutting mechanisms or cause system failure. Following proper waste disposal practices protects equipment integrity and prevents costly repairs. Most manufacturers provide specific guidelines regarding acceptable materials for their grinder pump systems.

How do I choose between leading grinder pump brands like Zoeller, Liberty, E/One, and Grundfos?

Selecting among top grinder pump manufacturers requires evaluating several factors: application requirements (residential versus commercial wastewater), horsepower rating needs based on total dynamic head and flow rate, warranty coverage, local service availability, pump energy efficiency specifications, and budget constraints. Environment One Corporation (E/One) pioneered low-pressure sewer technology and offers premium reliability; Liberty Pumps emphasizes serviceability; Zoeller Company provides exceptional longevity; Grundfos delivers advanced monitoring; Myers Pumps offers value-oriented solutions. Consulting with experienced grinder pump contractors familiar with your specific wastewater infrastructure requirements ensures optimal equipment selection.

What does it mean when my grinder pump alarm activates?

A grinder pump alarm notification system activates when wastewater levels exceed normal thresholds, indicating potential pump failure, power interruption, float switch malfunction, or check valve failure allowing backflow. When alarms sound, immediately cease all water usage and contact qualified grinder pump service companies. Most systems provide 12-24 hours of emergency storage capacity after alarm activation. Regular alarm system testing ensures proper function when needed. Modern systems with remote alarm notification capabilities provide smartphone alerts enabling faster response to operational issues, minimizing risk of sewage backup or property damage.

Have you encountered challenges with your wastewater management system? Are you considering grinder pump installation for your property? I encourage you to share your experiences, questions, or insights in the comments section below. Your perspective contributes valuable knowledge to our professional community navigating the complexities of modern wastewater infrastructure. For those seeking additional information on specific manufacturers or installation requirements in your region, please reach out to connect with experienced grinder pump contractors who can provide site-specific guidance tailored to your unique circumstances.