Beyond the Basement: Exploring Commercial and Industrial Pump Applications for Advanced Industrial Pumping Solutions in 2026

When most professionals think about pump technology, residential sump pumps often come to mind. However, the landscape of industrial pump applications and commercial pump systems has evolved dramatically, with 2026 bringing unprecedented advancements in fluid handling equipment. As someone who has consulted with facilities across multiple sectors, I’ve witnessed firsthand how sophisticated pumping solutions have become essential to modern operations. The transition from basic utility pumps to intelligent, automated industrial fluid systems represents a technological revolution that’s reshaping how businesses approach process fluid handling.

Today’s commercial and industrial environments demand pumping equipment that goes far beyond simple water transfer. From chemical processing plants to pharmaceutical manufacturing facilities, the right pump selection criteria can determine operational efficiency, energy consumption, and ultimately, profitability. Understanding the diverse applications and emerging pump technology advancements has never been more critical for facility managers, engineers, and operations professionals planning for 2026 and beyond.

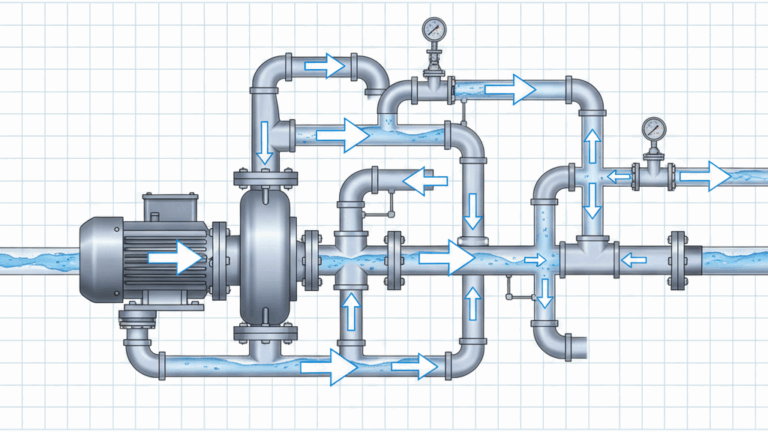

Centrifugal Pumps and Positive Displacement Pumps Transform Industrial Operations

The fundamental distinction between centrifugal pumps and positive displacement pumps continues to define pump selection criteria across industries. Centrifugal pumps dominate applications in water treatment facilities, HVAC systems, and municipal water systems due to their ability to handle high flow rates efficiently. These workhorses of industrial pumping solutions convert rotational kinetic energy into hydrodynamic energy, making them ideal for low-viscosity fluids and continuous operation scenarios.

Conversely, positive displacement pumps—including diaphragm pumps, peristaltic pumps, gear pumps, and screw pumps—excel in applications requiring precise flow control and the ability to handle high-viscosity fluids. Chemical processing plants and pharmaceutical manufacturing facilities increasingly rely on these pump types for accurate dosing and fluid transfer where maintaining constant flow regardless of pressure is paramount. The pump performance characteristics of positive displacement technology make them indispensable for process industry pumps requiring exceptional accuracy.

How Do Specialized Pump Types Address Industry-Specific Challenges?

Specialized variants like submersible pumps, sewage pumps, and slurry pumps address unique operational challenges across diverse sectors. Submersible pumps have revolutionized mining operations and wastewater management by operating completely submerged, eliminating priming issues while providing exceptional reliability. These commercial submersible pump solutions for 2026 incorporate advanced seal technology and bearing systems that extend operational lifecycles significantly compared to previous generations.

Meanwhile, slurry pumps designed for mining pumps and quarry pumps applications feature enhanced impeller design and wear-resistant materials to handle abrasive particles without compromising pump durability. Sewage pumps utilized in municipal wastewater pump applications 2026 now incorporate smart monitoring capabilities that predict maintenance needs before failures occur. This proactive approach to pump troubleshooting reduces downtime and operational costs substantially across commercial sewage pump systems for facilities.

Chemical Processing Plants and Water Treatment Facilities Drive Innovation

The demands of chemical processing plants have pushed manufacturers to develop pumps with superior chemical resistance and reliability. These industrial chemical transfer pump applications require materials that withstand corrosive substances while maintaining structural integrity under extreme conditions. Modern chemical industry pumps incorporate advanced materials like Hastelloy, PTFE, and ceramic composites, ensuring compatibility with aggressive chemicals while meeting stringent API standards and ISO certifications that govern pump specifications.

Water treatment facilities and desalination plants represent another critical application domain where pump technology advancements directly impact operational efficiency. These facilities deploy multiple pump types—from turbine pumps for high-lift applications to specialized positive displacement pumps for chemical dosing—creating integrated commercial water systems that process millions of gallons daily. The energy efficiency of these systems has become paramount, with variable frequency drives and advanced pump controllers reducing pump energy consumption by up to 40% compared to traditional fixed-speed installations.

What Role Does Industrial Automation Play in Modern Pump Systems?

The integration of Industry 4.0 principles with industrial automation has transformed commercial pump systems into intelligent, self-optimizing networks. IoT sensors continuously monitor hydraulic performance, flow control, and pressure management parameters, feeding data to SCADA systems that enable real-time pump performance optimization. This connectivity facilitates predictive maintenance strategies that identify potential issues before equipment failures occur, dramatically improving pump reliability across facility management pumps installations.

Pump controllers equipped with machine learning algorithms now adjust operational parameters automatically, optimizing pumping efficiency based on demand patterns and system conditions. This level of pump automation reduces human intervention requirements while maximizing pump lifecycle value. The implementation of such smart industrial pump systems for 2026 represents a fundamental shift from reactive maintenance to proactive pump operations management, delivering measurable improvements in both energy sector pumps performance and operational uptime.

Oil and Gas Industry and Mining Operations Require Robust Solutions

The oil and gas industry demands pumping equipment capable of withstanding extreme pressures, temperatures, and corrosive environments. Offshore pumps and marine pumps used in extraction and processing operations must meet rigorous ANSI specifications while delivering consistent performance under challenging conditions. Industrial oil and gas pump systems 2026 increasingly incorporate magnetic drive technology that eliminates shaft seals, preventing leaks and enhancing environmental safety—a critical consideration for offshore and shipboard pumps applications.

Mining operations present equally demanding requirements, where industrial slurry pump applications for mining must handle abrasive materials continuously without excessive wear. Leading manufacturers like Grundfos, Xylem, Sulzer, KSB, Flowserve, ITT Goulds, Pentair, and Ebara have developed specialized mining pumps featuring hardened components and advanced impeller design that extend maintenance intervals. These innovations in pump materials and pump components have significantly reduced total cost of ownership for mining pumps while improving operational reliability in quarry pumps applications.

Pharmaceutical Manufacturing and Food and Beverage Industry Standards

Pharmaceutical pumps require exceptional precision, cleanliness, and documentation to meet FDA regulations and maintain product integrity. Sanitary design principles govern every aspect of these commercial pharmaceutical pump applications, from surface finishes that prevent bacterial growth to seal-less magnetic drive pumps that eliminate contamination risks. The pharmaceutical manufacturing sector increasingly specifies peristaltic pumps and diaphragm pumps for their ability to handle sensitive fluids without cross-contamination while maintaining accurate flow control essential for batch consistency.

Similarly, the food and beverage industry demands hygienic pump design that meets stringent sanitation requirements. Food processing pumps, beverage pumps, dairy pumps, and brewing pumps must facilitate complete cleaning-in-place (CIP) procedures while handling products ranging from thin liquids to viscous slurries. Commercial food processing pump applications now incorporate 3-A sanitary standards and EHEDG certifications, ensuring compliance with food safety regulations. Advanced pump engineering has produced designs with minimal dead zones and smooth surfaces that prevent product buildup, enhancing both pump maintenance efficiency and product safety.

How Do Energy Efficiency Requirements Impact Pump Selection?

Energy efficiency has transitioned from a desirable feature to a mandatory requirement across most industrial and commercial applications. Power generation facilities and HVAC systems in commercial buildings represent massive energy consumers where optimizing pumping efficiency delivers substantial operational savings. Variable frequency drives (VFDs) have become standard components in pumping solutions, allowing pump speed adjustment to match system demand rather than wasting energy through throttling valves—a practice that reduces energy consumption by 25-50% in typical commercial HVAC pump systems for large buildings.

Cavitation prevention through proper pump design and installation represents another critical factor affecting both energy efficiency and equipment longevity. When cavitation occurs, it dramatically reduces hydraulic performance while damaging pump components through erosion. Modern pump station design incorporates computational fluid dynamics (CFD) analysis to optimize impeller design and system hydraulics, preventing cavitation while maximizing pumping capacity. These energy efficient commercial pump applications reflect the growing emphasis on sustainability and operational cost reduction that defines facility management priorities for 2026.

Industry Leaders Including Grundfos, Xylem, and Flowserve Shape Technology Direction

Major manufacturers continue to drive innovation through substantial research and development investments. Grundfos, Xylem, Sulzer, KSB, Flowserve, ITT Goulds, Pentair, and Ebara collectively set industry standards for pump technology, each bringing specialized expertise to different market segments. These companies’ commitment to advancing seal technology, bearing systems, and pump control systems ensures that commercial and industrial customers benefit from continuous pump technology advancements that improve reliability, efficiency, and operational flexibility.

The competitive landscape among these industry leaders has accelerated the adoption of smart pump technologies and IoT integration. Each manufacturer offers proprietary pump monitoring solutions that provide diagnostic capabilities, remote access, and predictive maintenance features. This focus on digital transformation aligns with broader Industry 4.0 initiatives, positioning pumps as connected assets within integrated industrial fluid systems rather than standalone mechanical devices. The result is a new generation of pumping equipment that delivers unprecedented visibility into pump operations and performance metrics.

| Application Sector | Primary Pump Types | Key Performance Criteria | Leading Manufacturers |

|---|---|---|---|

| Water Treatment Facilities | Centrifugal, Submersible, Turbine | Energy Efficiency, Reliability | Grundfos, Xylem, KSB |

| Chemical Processing Plants | Diaphragm, Gear, Magnetic Drive | Chemical Compatibility, Seal-less Design | Flowserve, Sulzer, ITT Goulds |

| Oil and Gas Industry | Screw, High-Pressure Centrifugal | Pressure Capability, Durability | Flowserve, Sulzer, KSB |

| Food Processing | Peristaltic, Sanitary Centrifugal | Hygiene, CIP Compatibility | Grundfos, Xylem, Pentair |

Frequently Asked Questions

What are the most common industrial pump applications beyond residential use?

The most common industrial pump applications include water treatment facilities, chemical processing plants, oil and gas operations, mining and mineral processing, pharmaceutical manufacturing, food and beverage production, power generation, HVAC systems for commercial buildings, wastewater management, and irrigation systems. Each application demands specific pump types based on fluid characteristics, flow requirements, pressure specifications, and environmental conditions.

How do I choose between centrifugal and positive displacement pumps for my facility?

Choose centrifugal pumps when handling high-volume, low-viscosity fluids at relatively low pressures, such as water transfer or HVAC circulation. Select positive displacement pumps when you need precise flow control, handle high-viscosity fluids, require self-priming capability, or must maintain constant flow regardless of pressure variations. Chemical dosing, thick slurries, and applications requiring metering accuracy typically favor positive displacement technology.

What pump technology advancements should I expect in 2026?

Key pump technology advancements for 2026 include widespread IoT sensor integration for predictive maintenance, AI-powered pump controllers that automatically optimize performance, advanced materials providing superior chemical resistance and wear properties, energy-efficient designs meeting stringent sustainability requirements, and seamless integration with Industry 4.0 platforms. Expect significant improvements in pump monitoring capabilities, remote diagnostics, and automated performance optimization across all commercial and industrial applications.

How can I improve energy efficiency in existing pump systems?

Improve pump energy efficiency by installing variable frequency drives to match pump speed with demand, replacing oversized pumps with properly sized equipment, implementing regular maintenance to prevent performance degradation, optimizing system design to reduce unnecessary friction losses, upgrading to high-efficiency pump models, and installing monitoring systems to identify inefficiencies. Proper pump selection, installation, and maintenance practices can reduce energy consumption by 30-50% in most commercial and industrial applications.

What maintenance practices extend industrial pump lifecycle?

Essential pump maintenance practices include regular vibration monitoring to detect bearing wear, periodic alignment checks, seal inspection and replacement before failure, lubrication according to manufacturer specifications, monitoring for cavitation signs, tracking performance trends to identify degradation, maintaining proper suction conditions, and implementing predictive maintenance using IoT sensors. Preventive maintenance programs typically extend pump lifecycle by 40-60% compared to run-to-failure approaches while reducing unplanned downtime significantly.