Top Signs Your Pump Needs Replacement vs Repair

When your pump starts showing signs of trouble, the decision between repairing it or opting for a complete replacement can be challenging. Understanding the key indicators that differentiate a minor issue from a major malfunction is essential to ensure reliable operation, preserve safety, and avoid unnecessary costs. In this guide, we’ll help you recognize the top warning signs of pump failure, explain when a simple repair will suffice, and reveal the situations where replacing your pump is the wiser choice for efficiency and peace of mind.

Key Highlights

- Early signs of pump failure include unusual noises, leaks, and electrical faults, requiring prompt attention to prevent major issues.

- Deciding between pump repair and replacement depends on cost-effectiveness, part availability, and long-term efficiency.

- Poor installation, electrical surges, and lack of regular maintenance significantly reduce sump pump lifespan and reliability.

- Persistent performance issues or recurring repairs may indicate it is time to consider a pump system upgrade.

- Professional pump maintenance helps detect early issues, extends pump life, and ensures energy-efficient operation.

Common Warning Signs Your Pump May Be Failing

Identifying when your pump needs repair is crucial to protecting your home from water damage and ensuring efficient plumbing operation. One of the most noticeable indicators is unusual noise coming from the pump. If your sump pumps, submersible pump, or heat pump start rattling, grinding, or making excessive humming sounds, this often points to worn components or alignment issues. Persistent noises shouldn’t be ignored, as they can lead to more severe problems if left unchecked.

Leaks are another common symptom that your pump may be compromised. If you observe water pooling near your pump, investigate for cracks or worn-out seals. Any water pump with leaks is less effective at transporting or circulating water, which means your system could soon fail altogether. Issues with the pump switch are also cause for concern. If the switch becomes stuck or fails to engage, your pump might not activate when needed, raising the risk of flooding or backup in the drain.

Electrical faults represent an often-overlooked factor in pump performance. Fluctuations in power supply or frequent circuit trips are warning signs that internal electrical repair parts or wiring may be defective. In both residential and commercial plumbing systems, a pump that runs constantly, cycles irregularly, or fails to shut off is at risk of overheating or burning out. Spotting these issues early can save you from a costly replacement scenario down the line. If you’re unsure whether it’s time for pump repair or full pump replacement, consulting PumpPros can help you determine the best solution tailored to your specific pumps and plumbing needs.

Repair Services vs. Replacement: Making the Right Choice

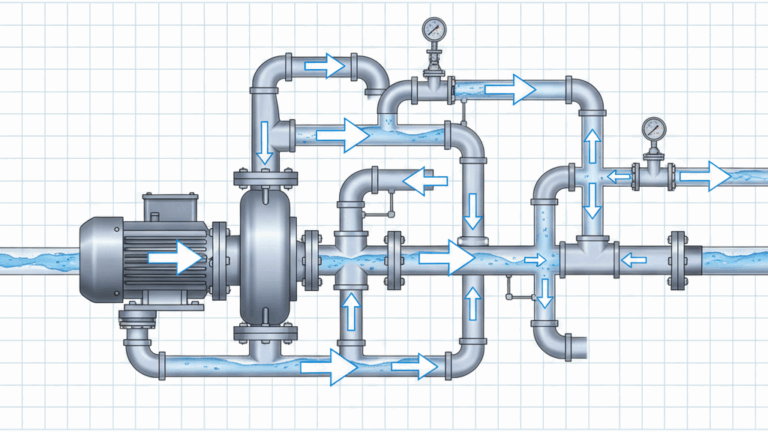

Deciding between repair services and a full replacement for your pump system is a major factor in maintaining optimal performance and cost-effectiveness. Understanding the pros and cons of pump repair versus opting to replace a unit will help protect your home’s plumbing and water management systems. This balance is especially important for centrifugal pumps, irrigation pumps, transfer pumps, and water pumps, where reliability, installation quality, and maintenance costs can quickly escalate. Weighing long-term efficiency, part availability, quieter operation, and service lifespan gives you a clear roadmap for the best way forward, whether you need minor repairs, comprehensive parts replacement, or a completely new installation. Let’s compare how cost, efficiency, and practical considerations affect your decision.

Evaluating the Cost and Efficiency of Pump Repair

Choosing between repair services and replacement involves assessing the true cost-effectiveness and efficiency of your pump over its life cycle. Pump repair can be a highly cost-effective solution, especially when the issue is limited to repair parts such as seals, electrical components, or worn bearings. A quick repair for a centrifugal pump, transfer pump, or irrigation pump can restore water pumps to optimal performance, ensuring your plumbing and water supply systems run seamlessly. However, it’s crucial to consider the age of your pump and the frequency of service calls. If you’re scheduling frequent repairs for the same pump, recurring costs add up, and that money could be better spent on a new installation altogether.

Efficiency drops significantly with repeated breakdowns, particularly for older centrifugal pumps and irrigation pumps. When a pump requires constant maintenance, it often consumes more power, leading to increased electrical costs. Addressing mechanical and electrical issues with proper pump repair may temporarily restore efficiency, but if quieter operation and long-term reliability are important factors, replacement might be more beneficial. Newer water pumps are engineered for quieter operation and improved energy efficiency, which can have a significant impact on your home’s energy bills and overall plumbing performance.

Don’t overlook the availability of parts and specific requirements for your pump. For older pump models, sourcing compatible repair parts may be challenging and more expensive, pushing the cost of repair services closer to the price of a replacement. When it comes to ensuring a reliable water supply, minimizing downtime, and maximizing pump lifespan, reviewing all these elements is essential. For those considering the best manufacturers or upgrades, check out pump manufacturers for a wide selection of high-efficiency pumps, replacement parts, and expert installation services. By comparing ongoing maintenance, electrical consumption, installation expenses, and part costs, you’ll make a well-informed decision on whether to repair or replace your pump for lasting performance in any plumbing or home application.

Specific Issues That Affect Sump Pump Lifespan

Several key factors directly impact how long your sump pumps perform reliably in your home. One of the primary influences is the quality of initial installation. Even the most robust submersible pump can’t overcome poor setup, uneven placement, improper plumbing connections, or a misaligned drain, which can cause the unit to work overtime or cycle irregularly. This extra strain not only accelerates wear but also increases the risk that your pump needs repair earlier than expected. Faulty or mismatched parts during installation may further reduce longevity, and even minor leaks developing at joins can lead to performance loss and water damage.

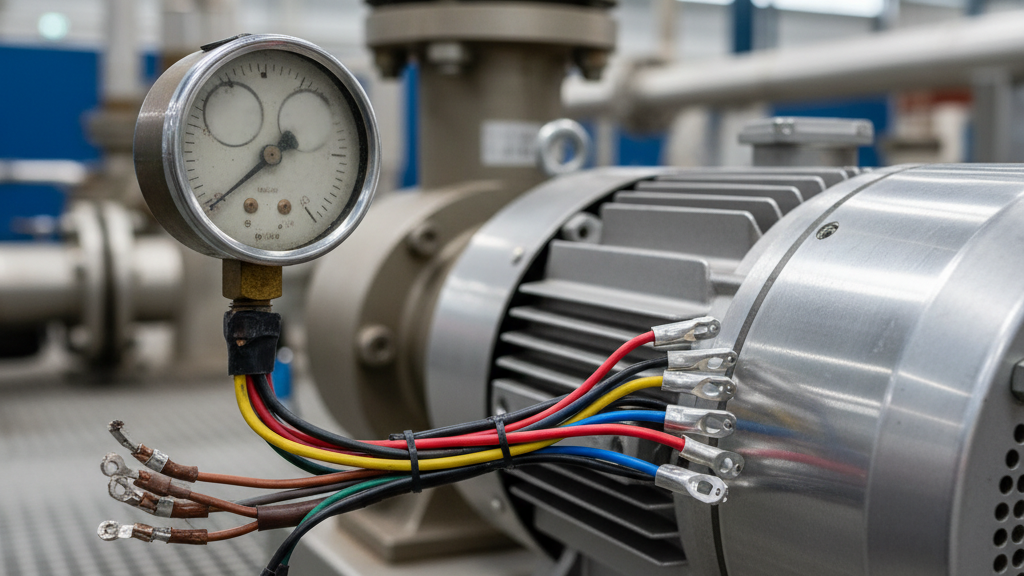

Frequent or severe electrical surges pose another threat to sump pumps. Since a water pump relies on consistent power, even minor electrical fluctuations can damage sensitive components such as the pump switch or motor. Over time, corroded contacts and shorted wires demand professional repair services, and if left unchecked, these electrical issues will cut the lifespan of both the pump and its critical repair parts. Inconsistent power may cause the unit to run constantly, overheat, or fail to start during emergencies.

Routine maintenance, or the lack thereof, is a pivotal factor as well. Neglecting regular inspections allows debris to accumulate in the pit or drain, overloading the pump and reducing efficiency. Clogged components in a centrifugal water pump suffer from increased friction and diminished output. Failing to address leaks, clean the impeller, and replace worn parts through timely repair of centrifugal measures not only reduces efficiency but also shortens total service life. Investing in professional services for ongoing maintenance can resolve emerging issues before they require full replacement, ultimately keeping your home protected while extending the lifespan of your plumbing systems.

Symptoms of a Failing Water Pump

A failing water pump in your home can present a wide range of warning signs that, if caught early, can spare you costly breakdowns and extensive repairs. One of the most common symptoms is the presence of unusual noise coming from the pump during operation. Whether it’s a centrifugal pump or a transfer pump, rattling, grinding, or whining sounds can quickly indicate worn bearings or other internal repair parts needing attention. If these noises persist even after basic maintenance, it may signal deeper issues within the plumbing or electrical systems tied to the water pump.

Leaks also stand out as a clear indication of pump trouble. Puddles or wet spots around the water pump usually mean that seals or other mechanical components have deteriorated, requiring urgent pump repair or replacement. Consistently finding water around the pump, regardless of the type, be it a centrifugal pump, sump pump, or transfer pump, demands immediate investigation to prevent further water damage to your home’s foundation or plumbing. Leaks not only shorten the pump’s lifespan but also impact water conservation and system integrity.

Beyond visible and audible symptoms, inconsistent or unreliable performance is another hallmark of a failing pump. If your pump frequently cycles on and off, won’t start, or keeps running without shutting off, these issues might stem from electrical faults, worn-out switches, or failing internal components. Such malfunctions typically require prompt pump repair or, in severe cases, a decision to replace the entire unit. Regular maintenance, professional diagnostic services, and the use of quality replacement repair parts are essential practices to instill confidence in your system’s longevity. Ultimately, early intervention not only reduces the risk of complete failure but also ensures efficient plumbing and electrical operation throughout your home.

When to Consider Upgrading Your Pump System

Recognizing when to upgrade your pump system can be transformative for your home’s plumbing, water management, and overall efficiency. While previous discussions highlighted symptoms that signal urgent pump repair or replacement, there comes a point when simply repairing parts or performing maintenance is no longer cost-effective. Upgrading a water pump, sump pumps, irrigation pump, or even a heat pump often delivers significant improvements in quieter operation, energy savings, and system reliability. It’s important to weigh the benefits of newer pumps, improved installation practices, and advancements in electrical controls against ongoing costs and recurring repairs. Choosing an upgrade can mean more than just replacing a worn system; it’s about investing in the long-term health and value of your home.

Long-Term Benefits of Professional Pump Maintenance

Regular professional pump maintenance is truly the backbone of any reliable system, whether you’re working with sump pumps, a water pump, or a modern heat pump. While earlier content addressed immediate warning signs and repair services, committing to a routine maintenance schedule with trusted professionals can significantly prolong the life of your pumps and delay the need to upgrade or replace them outright. Well-maintained systems, equipped with quality repair parts, consistently deliver efficient water flow for plumbing and irrigation pump needs, reducing the risk of unexpected breakdowns that can lead to costly emergency replacements or installations.

One of the biggest advantages of professional maintenance is the early identification of issues in critical components such as electrical wiring, switches, or worn parts. Technicians can spot emerging problems before they escalate, ensuring continual protection for your home’s plumbing and minimizing unnecessary downtime. In addition, professionals often recommend upgrades that enhance quieter operation and performance, like replacing outdated transfer pump models with high-efficiency water pumps or integrating the latest electrical controllers for improved reliability.

Investing in regular pump repair services doesn’t just preserve your system; it keeps efficiency at its peak. Clogged impellers, minor leaks, or electrical inconsistencies in a pump may seem insignificant, but left unresolved, they can result in power wastage and greater wear on the system. By partnering with experts for both maintenance and installation, homeowners gain insights into the optimal time for an upgrade based on actual performance data, not just age or visual wear. Ultimately, this strategic approach maximizes equipment lifespan, keeps your energy bills lower, and staves off the bigger expense of a full upgrade until it’s truly necessary, all while ensuring safe, reliable, and quieter operation throughout every season.

Here are some key advantages you can expect from a proactive pump maintenance plan:

- Minimizes unexpected equipment failures and emergency downtime.

- Extends the operational lifespan of pump systems.

- Improves overall energy efficiency and reduces running costs.

- Helps identify minor issues before they lead to major repairs.

- Ensures consistent system performance and reliability.

- Supports regulatory compliance and safe operations.

- Simplifies budgeting by reducing the risk of costly surprises.

Prioritizing proactive maintenance safeguards your investment and delivers peace of mind for daily operations.

Recognizing whether your pump needs repair or replacement is crucial for avoiding costly downtime and ensuring optimal performance. By staying attentive to warning signs and consulting with a knowledgeable technician, you can make the right decision for your specific situation. Regular maintenance and timely action will help prolong the life of your pump and maintain system efficiency. If you’re unsure about the next steps, don’t hesitate to reach out to professionals who can assess your pump and provide expert recommendations tailored to your needs. Prioritizing prompt attention can save both time and resources in the long run.

FAQs

What are the common warning signs that my pump may be failing?

Early signs of pump failure include unusual noises (such as rattling, grinding, or excessive humming), leaks around the unit, and electrical faults like frequent circuit trips or irregular cycling. Addressing these symptoms quickly can help prevent further damage or costly breakdowns.

When should I repair my pump versus replacing it completely?

Pump repair is ideal when issues are minor, such as worn seals or electrical parts, and the overall unit is still efficient and reliable. Replacement is preferable if breakdowns are frequent, repair costs add up, parts are hard to find, or the pump is old and inefficient.

How does poor installation affect pump lifespan?

Poor installation—including improper placement, plumbing misalignment, or the use of mismatched parts—can cause the pump to work harder, wear out faster, and experience more frequent failures, even if the pump itself is high quality.

What routine maintenance does my pump need for optimal performance?

Regular professional maintenance includes inspecting for leaks, cleaning the impeller, checking electrical connections, and replacing worn parts. Consistent maintenance extends pump life, boosts efficiency, and reduces the risk of sudden failures.

What are the benefits of upgrading my pump system?

Upgrading to a newer or high-efficiency pump can provide quieter operation, improved energy savings, and greater reliability. Modern pumps and controls also help reduce frequent repairs, downtime, and unnecessary energy usage in the long term.