Beyond the Basement: Exploring Commercial and Industrial Pump Applications for 2026

While many people associate pump systems with residential sump pumps or basement flooding prevention, the reality is that pumps are foundational to a wide range of commercial and industrial operations. As we head into 2026, pump technology is rapidly evolving to meet the growing demands of businesses, municipalities, and industrial facilities. From wastewater management to process fluid control, advanced pump systems are playing a crucial role in infrastructure and operations far beyond the residential basement.

At Pump Professionals, we specialize in the maintenance, installation, and service of pumps across all sectors. As experts in both traditional and cutting-edge pump applications, we’re taking a closer look at where pump systems are headed in 2026—and how they’re transforming commercial and industrial operations across the country.

Emerging Trends in Commercial and Industrial Pump Applications

The pump industry is undergoing a shift toward smarter, more energy-efficient, and application-specific systems. Here are some of the trends shaping pump usage in commercial and industrial settings:

- Automation & Smart Controls: Digital monitoring and remote diagnostics are becoming standard, allowing facilities to track flow rates, pressure, and pump health in real-time.

- Energy Efficiency Mandates: High-efficiency motors and variable frequency drives (VFDs) are increasingly being integrated to reduce energy costs and environmental impact.

- Industry-Specific Customization: From food processing to manufacturing, tailored pump configurations are improving productivity and system reliability.

- Predictive Maintenance: Data-driven maintenance scheduling is replacing reactive service, helping reduce downtime and extend equipment life.

Key Commercial Pump Applications for 2026

Commercial properties depend on pumps for a range of essential services, and these needs are only expanding as new building codes and operational demands evolve. Below are some of the most important commercial pump applications projected to grow in 2026:

1. Stormwater and Drainage Management

With increasing rainfall intensity and urban development, commercial properties rely on high-capacity stormwater pumps to protect buildings, parking structures, and landscaped areas. Stormwater systems are often integrated with smart controllers for automatic response during weather events.

2. Commercial Sump and Sewage Pumps

Retail, office, and hospitality buildings frequently use sump and sewage ejector pumps to manage wastewater from lower levels. These pumps are built to handle higher volumes and heavier-duty cycles than residential models.

3. Booster Pumps for Water Pressure

Booster pump systems ensure adequate water pressure across multi-story buildings and large commercial facilities. These systems are especially important in healthcare, hospitality, and multi-tenant buildings where consistent pressure is a service priority.

4. HVAC Circulating Pumps

Heating and cooling systems in commercial buildings depend on circulating pumps to maintain temperature consistency and energy efficiency. Modern systems often integrate VFDs and building automation interfaces for optimized control.

5. Grease and Oil Interceptor Pumps

Restaurants, cafeterias, and commercial kitchens require pumps capable of moving grease-laden wastewater to interceptors. These specialized pumps are engineered to resist clogging and chemical degradation.

Industrial Pump Applications: Driving the Backbone of Production

In industrial environments, pump systems must deliver continuous, reliable service under demanding conditions. Downtime can lead to production halts, compliance violations, and safety risks. Here are some of the key industrial pump applications trending in 2026:

1. Wastewater and Effluent Treatment

Industrial facilities generate significant wastewater that must be processed before disposal or reuse. High-volume effluent pumps and chemical feed systems are critical components of treatment plants, helping meet environmental and discharge standards.

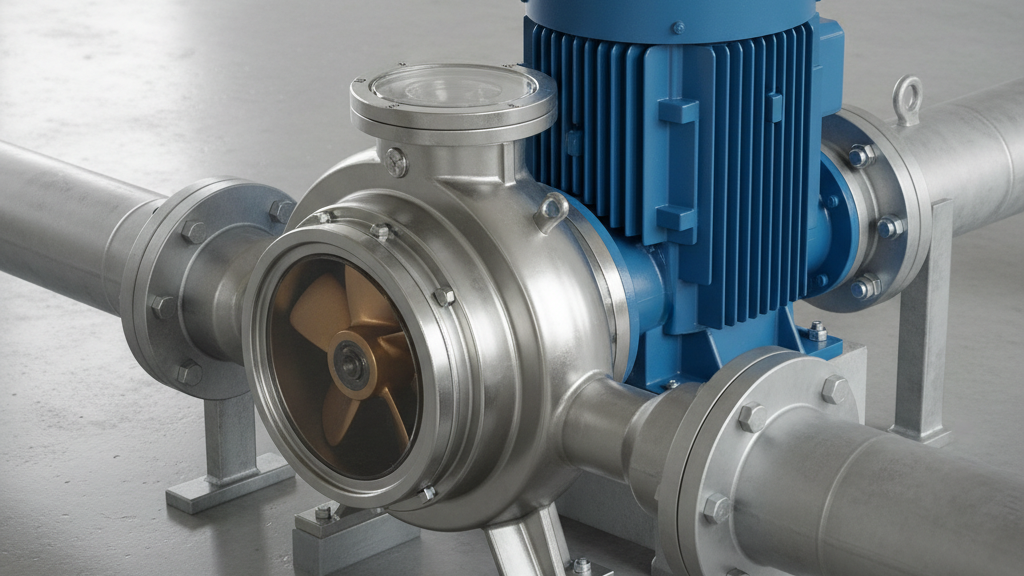

2. Process Pumps for Manufacturing

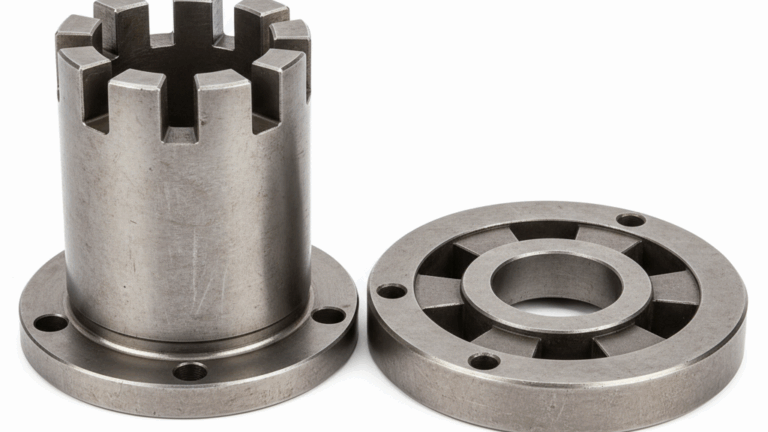

In sectors like pharmaceuticals, food and beverage, and chemicals, process pumps transport fluids through various production stages. These pumps must be corrosion-resistant, precise, and easy to maintain for maximum uptime.

3. Cooling and Heat Transfer Systems

Manufacturing equipment often relies on pumps to circulate coolant or heat transfer fluids. Pump systems must be properly sized and maintained to prevent overheating and production slowdowns.

4. Slurry and Solids Handling

Mining, pulp and paper, and construction industries require pumps that can move abrasive or solid-laden fluids. Slurry pumps are engineered with durable materials to withstand high-wear environments.

5. Chemical Transfer Pumps

From agricultural operations to industrial cleaning systems, chemical transfer pumps handle aggressive or hazardous fluids. Material compatibility and leak prevention are critical design considerations for these applications.

Planning for 2026: What Facilities Should Be Doing Now

As commercial and industrial pump applications become more specialized and regulated, facility managers, engineers, and maintenance teams need to prepare. Here are a few action steps to ensure your pump systems are ready for the year ahead:

- Evaluate Your Current Pump Systems: Identify outdated or underperforming equipment that may require upgrades.

- Schedule Preventative Maintenance: Regular inspections help prevent downtime and extend system lifespan.

- Assess for Automation Opportunities: Implementing smart controllers or remote monitoring can improve performance and reduce labor costs.

- Work with Industry Experts: Partnering with a pump service provider that understands your application ensures better outcomes and compliance.

The Pump Professionals Advantage

At Pump Professionals, we go beyond just supplying or installing pump systems. We provide turnkey services including system design consultation, maintenance programs, emergency repairs, and long-term pump performance strategies for commercial and industrial clients.

Our experience across a wide range of industries allows us to understand the unique needs of each facility. Whether you’re upgrading a legacy HVAC system, expanding a processing line, or planning for stormwater compliance, we offer the technical expertise and service reliability you can count on.

Contact Us to Prepare Your Pump Systems for 2026

2026 brings new challenges and opportunities in pump system design, usage, and maintenance. From smart commercial booster systems to rugged industrial slurry pumps, we can help you plan, maintain, and optimize your systems for long-term performance.

Contact us today to schedule a consultation or maintenance service with our team of pump experts. Let Pump Professionals help keep your commercial or industrial operations flowing smoothly into the future.